Quartz Stone Processing Plant Silica Sand Washing Machine

Basic Info

Model No.: 3200

Product Description

Quartz stone processing plant refers two processes, one is quartz stone crushing and screening process, the other is washing and drying process, the first one is used to crush quartz stone into small sand, and the later one is used to remove the impurities mixed in the silica sand, such as clay and iron, the first process mainly includes primary crusher, vsi sand maker, vibrating screen, while the second process mainly consists of sand washing machine, fine sand recycling device, rotary dryer, and belt conveyor. as for the stone washing machine, there are two types available, spiral sand washing machine and wheel sand washing machine. our factory can provide the compelte quartz stone processing plant, whatever it's for artificial sand processing plant or Silica Sand Washing Plant. we will provide the suitable solution according to your specific requirements.

Silica Sand Washing Plant is a reletively simple stone cleaning process that removes the clay or dust mixed in the stone or sand, there are mainly two types of stone washing machine, one is spiral type stone washer and the other is wheel-bucket stone washing machine, both can be effectively used for the washing purpose. besides, both of the two stone washing machines have the other two functions, namely, classifying and dehydration, the stone and gravel can meet the construction standards for gravel and river stone, both of them are widely used for construction site, sand and stone manufacturing plant, glass making plant.

How is wheel bucket stone washer works in a Silica Sand Washing Plant

The gravel is fed to the washing tank of stone washer with belt conveyor, with the rotation of the wheel, the stone gravels grinds and makes the impurities separated from the stone gravel, and there is screen sieve on the rotation wheel, the clean stone is separated when the bucket move out of the water tank, then discharges on a belt conveyor and transports to a designed distance.

So we can find that a compete Silica Sand Washing Plant mainly consists of belt conveyors and stone washing machine, it needs to use 1- 2 sets of stone washer according to the content of the impurty, to make sure the finished stone can meet the standard required.

Technical parameter of wheel bucket stone washing machine used for Silica Sand Washing Plant

| Model | Wheel Dia (mm) | Capacity (t/h) | Sand return Capacity(t/h) | Rotate Speed (r/min) | Power (kw) | Weight (kg) |

| MY2010 | Φ2000 | 8-40 | 3-8 | 1-2 | 4 | 2000 |

| MY2612 | Φ2600 | 20-100 | 5-15 | 1-2 | 5.5 | 3500 |

| MY2814 | Φ2800 | 30-150 | 8-20 | 0.8-1.5 | 11 | 5200 |

| MY3014 | Φ3000 | 50-200 | 10-30 | 0.8-1.5 | 15 | 7800 |

| MY3214 | Φ3200 | 100-280 | 15-40 | 0.8-1.5 | 15 | 8800 |

| MY3616 | Φ3600 | 130-460 | 30-60 | 0.8-1.5 | 18.5 | 14200 |

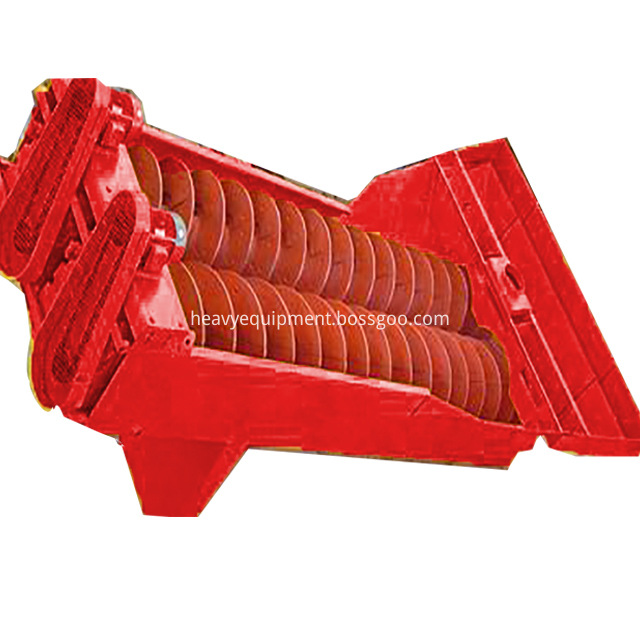

Spiral Stone washing machine, or spiral stone washing machine, screw stone washer, is a dust cleaning device which is used for dust or clay removing that mixed in the stone, sand, or some mines, there are single spiral stone washer and double-spiral stone washing machine, single type is mainly for small capacity processing while the double-spiral type is mainly for big processing capacity, the sprial stone washer can be used for stone washing purpose in construction site, artificial sand processing plant, Silica Sand Washing Plant, coal washing plant, placer gold washing plant, and so on. the impurity can be less than 1% after washing process.

For a stone crushing project or the sea sand, some clay or dust presents in the sand, which affects the quality of the sand, so it's necessary to clean the them from the sand before using for the new projects, nowadays there are mainly three types of sand washing machine, one is wheel type stone washer, the second is sprial sand cleaning machine, the third is trommel screen with water flushing.

Spiral stone washer, also know as spiral sand washing machine, screw stone washer and screw sand washing machine, it needs to installed with some inclination, around 15 degree, when the spiral sand washer is working, with the rotating of the screw, on one hand it mix the sand with water and the clay is dissolved in the water, on the other hand, the sand will be transported to the higher end, and there is an outlet at the bottom of the spiral stone washer, where the washed sand is discharged and transported to a designed distance.

However, there is some portion of fine sand go away with the clay, so it`s necessary to recover the sand with a fine sand recovery machine, after recycling, the profit is increased as there`s less loss of fine sand.

For the spiral stone washer, the diameter of the spiral can be from 500mm to 3000mm, the length usually ranges from 5000mm to 7500mm. And for some big capacity, the quantity of the spiral can be doubled. That`s to say, there are two spirals in the tank of spiral stone washer.

As to the washing principle of the spiral stone washer, it`s driven by motor via gearbox, which transmit the power to the rotating spiral, then the spiral rotates, the fresh water is fed at the bottom of the spiral stone washer, and the waste water will be discharged at the top part of the spiral stone washer due to overflow function.

Technical parameters of spiral sand stone used for Silica Sand Washing Plant

| Model | XL508 | XL610 | XL762 | XL915 | 2XL915 | XL1115 | 2XL1115 |

| Screw Diameter(mm) | 508 | 610 | 762 | 915 | 915 | 1115 | 1115 |

| Length of Tub(mm) | 6705 | 7225 | 7620 | 7585 | 7585 | 9782 | 9782 |

| Max Feed Size(mm) | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 | ≤ 10 |

| Capacity | 20 | 40-50 | 50-75 | 100 | 200 | 175 | 350 |

| Speed of Screw | 38 | 32 | 26 | 21 | 21 | 17 | 17 |

| Motor Power | 5.5 | 7.5 | 11 | 11 | 2×11 | 15 | 2×15 |

| Water Consumption(t/h) | 6-60 | 6-63 | 9-63 | 10-80 | 20-160 | 20-150 | 40-300 |

| Overall Dimensions(mm) | 8000×2343 | 8000×2050 | 8545×2650 | 8500×2810 | 8420×3765 | 10970×3945 | 10970×5250 |

| Weight(t) | 2.67 | 3.80 | 5.23 | 6.27 | 11.11 | 10.18 | 17.94 |

For the application of spiral sand wahser, besides the sand, it can be also be used for coal washing, clay and impurities washing purpose in some ore processing plant, such as gold, manganese ore, and it can be also used a classifying machine in the ore beneficiation plant, which is widely used nowadays

Features of spiral stone washer used for Silica Sand Washing Plant

1.Heavy duty, long service life and no quick-wear part.

2.High washing, dewatering and classifying efficiency.

3.Economic and strong frame structure.

What do we offer?

1: Stone crushing and screening plant.

2: Sand and gravel washing and drying plant.

3: Ore beneficiaton plant, such as gold ore, zinc ore, graphite, chromite ore, iron ore, cobalt ore, nickel ore, etc.

4: Cement production plant.

5: Lime manufacturing plant.

6: LECA/Oil proppant production plant.

7: AAC block manufacturing plant.

8:Designing based on client's specific requirements.

9: Equipment production.

10: After sale service, we will send our engineer to the client's factory to guide the installation, commissioning, training, etc. until the whole project runs smoothly.

11: Long-term Spare Parts supply.

More question, welcome to send us your inquiry to our sales team.

Product Categories : Crushing And Screening Machine > Sand Washing Machine